Professional Infrared Thermography

Safety, Savings, Prevention

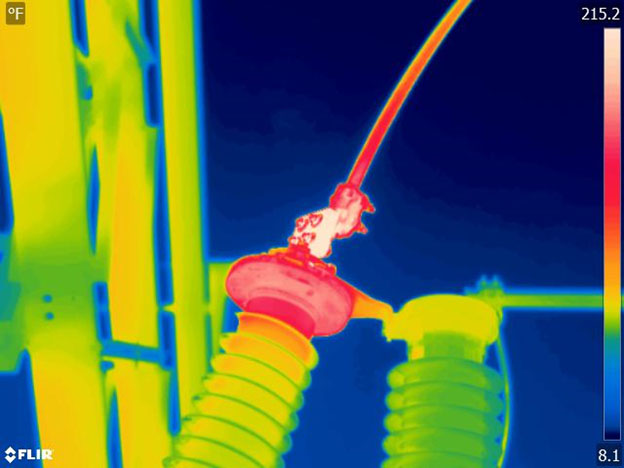

Electrical systems are susceptible to failure, often with little or no warning. These failures can result in runaway thermal events causing fires, equipment damage, and personnel injury.

Infrared Thermography is a valuable tool in detecting increased heat in electrical components, allowing them to be inspected and repaired before problems advance to critical failure.

Iris Associates brings more than 25 years of experience to the inspection of your facility. Using state-of-the-art infrared thermography inspection equipment and techniques, we detect conditions such as faulty wiring, overloads and unbalanced loads, loose connections, inductive heating, and defective equipment.

Routine, timely inspections using infrared thermography prevent hazardous conditions from resulting in injury, equipment loss, costly downtime, and lost productivity. Preventing a single facility fire pays for years of quality, cost-saving inspection work, not to mention the added benefits of in lowering insurance premiums and minimizing equipment repair costs.

Best of all, infrared thermography can be performed while systems are running, without interrupting daily production or activity. Less downtime, increased productivity, and improved safety all directly add to your bottom line.

At IRIS Associates, our job helps your business succeed.

Would you like to learn more? Contact Us today or give us a call at 814-730-3567.

Serving Pennsylvania, Ohio,West Virginia and beyond.

- Power Generation

- Petro-Chemical

- Coal Mining

- Manufacturing

- Hardwood Lumber

- Metal Refining and Processing

Contact

IRIS Associates

When you contact IRIS Associates to perform infrared thermography inspections, Mr. Schmidt will personally schedule your work, perform the survey with your company’s personnel, and prepare the report. The level of performance and personal attention throughout the entire inspection process is unmatched within the industry.